Introduction: HC micro fluid control products, such as flow restrictors, check valves, shuttle valves, etc.; are widely used in the field of fluid control. such fluid control products require precise fluid control control to avoid vortices, local pressure rises, howling and other phenomena during the fluid flow process; these will make the fluid control system unstable, generate large amounts of heat, and be difficult to control. in order to effectively reduce and eliminate the above problems, hongchuang company began to use professional simulation software to simulate possible problems and risk points from the product design stage, and then modified design, sample trial production, practical verification and many other links to ensure high quality. high-quality fluid control products, because of such multi-process control, make hongchuang’s microfluidic products more and more trusted and satisfied by customers.

SIGNIFICANCE OF FLUID SIMULATION

modern product requirements need to be implemented with modern ideas and tools; we know that the rigidity, strength, life, etc. meet lightweight, low-cost, efficient and reliable product development; similarly, in the field of fluid control, there are similar software for fluid motion analysis, which can help us effectively improve design, find problems in the early stage of design, and optimize products in the later stage , to help achieve the product optimal solution.

for a more complex fluid system, the flow of liquid in the pipeline and in the valve body is very complicated. if the design is not well considered, it is easy to generate vortex flow locally in the system, and the system will vibrate, howl, generate heat, and have low efficiency. bad question. if the simulation software can be used to simulate well in the early stage, the above problems will be effectively avoided. therefore, fluid simulation is very important for product development and improvement.

below we use several flow control products of HC company to share the application of how to solve problems through fluid simulation.

THE PRACTICE AND APPLICATION OF FLUID SIMULATION IN THE DEVELOPMENT OF RESTRICTOR

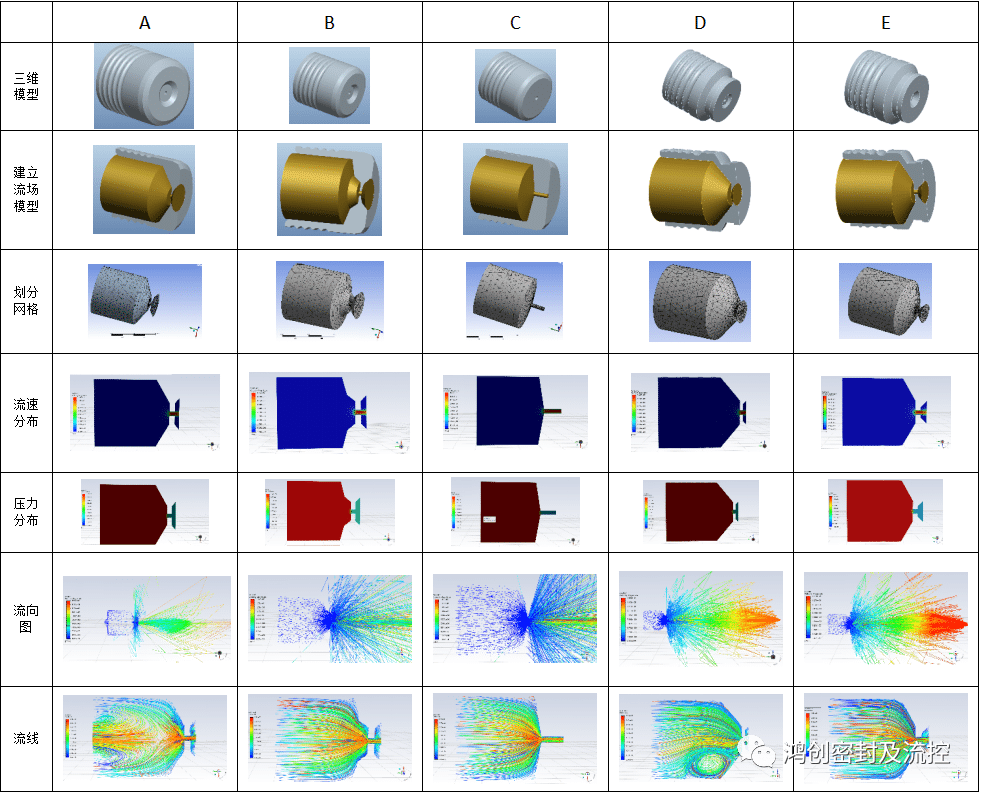

hongchuang developed a current limiter for a customer. according to the needs of customers, HC has designed a total of 5 schemes. see the list below for details. the schemes are a, b, c, d, and e. the difference between the schemes is , the angle before and after the liquid flows into the restrictor, the length of the restrictor hole, etc.

hongchuang has passed a fluid simulation software, professional simulation analysis, and the analysis results are as follows:

as can be seen from the figure above:

1. scheme a: there is backflow of the fluid before flowing into the restrictor, but after flowing out of the restrictor hole, the flow direction is clear and not messy; it is more suitable for occasions that require higher flow stability;

2. scheme b: there is no backflow of scheme a when flowing into the restricting hole, but the flow direction after flowing out of the restricting hole is more chaotic than that of scheme c;

3. plan c: compared with plan b, the flow direction after flowing through the restrictor hole is more orderly, and there is no backflow before the fluid flows into the restrictor hole, turbine, etc., which is a more commonly used restrictor function;

4. scheme d: it is obvious that there is a vortex circuit before the inlet of the flow limiting hole; it may cause howling, heat, etc. after flowing through the flow limiting hole, the pressure at the tip is higher, which can be understood as a large pressure loss ;

5. scheme e: better than scheme d, there is no eddy current circuit in the inflow 2, but the streamline is also more messy.

from the above scheme cases, it can be seen that in the initial stage of the design of the current limiter, the advantages and disadvantages of the scheme and the existing problems can be well compared through the simulation software, so as to avoid “stepping on thunder” in the later stage. judging from HC many years of practical experience, the actual situation is basically very similar to the simulation results. the simulation is also based on mathematical calculations, which is also scientific, and the simulation has practical significance.

PRACTICE AND APPLICATION OF FLUID SIMULATION IN CHECK VALVE OPTIMIZATION

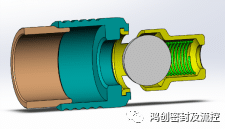

the picture below is a certain check valve of our company. for a customer with special needs, the customer hopes to make the flow as large as possible on the basis of further modification. in fact, this check valve of our company can meet the customer’s requirements. , but taking into account the pressure loss, heat and other conditions. after our research, we can make a simple modification to this valve: enlarge the inner hole, make the diameter of the ball larger, and redesign and adjust the spring seat at the same time.

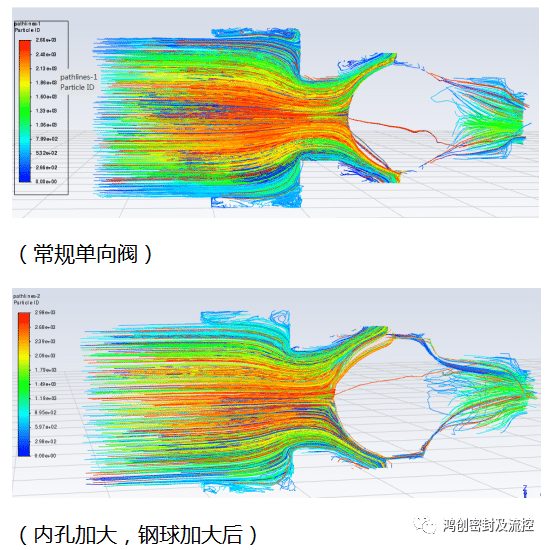

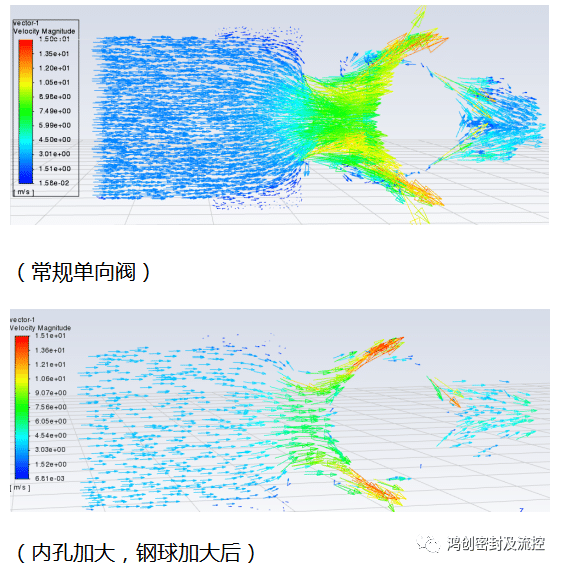

however, after adjusting the design, new problems may appear: although the inner hole is larger, the flow through it becomes larger, but at the same time, the sphere also becomes larger. after the sphere becomes larger, it will occupy more space for the fluid to flow through, and it will what is the result of squeezing the space through which the fluid flows, or can it be practiced only after the conclusion of the fluid simulation is obtained.

THROUGH MODELING AND SIMULATION ANALYSIS, AS SHOWN IN THE FIGURE BELOW:

through the simulation analysis: the inner hole of the check valve is increased, the steel ball is added, and the system pressure is at a standard atmospheric pressure, the flow rate is increased from the original 3.84l/min to 5.4l/min. through the simulation comparison analysis, it is known that the increase what size, how much flow increases. there is an intuitive understanding, and at the same time, new problems after the size becomes larger can also be seen through the simulation data, which can be effectively noticed and solved in later practice.

conclusion: through the above two actual cases, the analysis illustrates the practical significance of fluid simulation in product development, optimization, and improvement. it is precisely because of hongchuang’s professional attitude, the purpose of keeping improving products to customers, and insisting on adopting modern design simulation analysis methods make fluid control products more and more praised and recognized by customers. hongchuang will insist on making good use of fluid simulation tools to develop existing products and customized products for customers, improve efficiency, and find the optimal solution for service.

believe in professionalism! believe in HC microfluidic control products!