Design Metal Expansion Plugs

Expansion plugs design

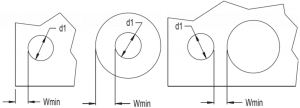

MINIMUM WALL THICKNESS AND DISTANCE FROM EDGES

Radial expansion of plugs causes plastic deformation in the material around the plug housing. A wall thickness and edge distance must be maintained to optimize the strength of the mechanical connection between the cap and the housing. The operating hydraulic pressure, the thermal cycle, the type of plug and the characteristics of the support material are all parameters to be considered for the determination of the minimum distance values and wall thickness.

Guidelines for determining the minimum wall thickness and minimum edge distance (Wmin) are given below. These minimum values to be respected mean that only a slight deformation of the external profile of a value of less than 20mm is produced. This does not affect the performance of the plugs. If the minimum recommended Wmin values are not respected, the support material can be overloaded, affecting the performance of the plugs.