Series – EXP RLC metric

Series HC EXP-RLC Metric

Pull Rivet Metal Expansion Plugs

Sleeve – Stainless Steel

Stem – Stainless Steel

Toll*: Material <280HB Hole Tolerance 0/+0.12mm

Material >280HB Hole Tolerance +0.05/+0.15mm

ON DEMAND HIGH PRESSURE VERSION

HOLE PREPARATION

Refer to the data in the catalog to determine the diameter and tolerances of the plug seat (D3).

- The roundness of the hole must be within 0.05mm

- The roughness of the hole must be between Rz 10-30 – Ra3.2-6.4 especially for hard materials

- Spiral or longitudinal scratches should be avoided as they can affect the performance of the plug

- Make sure the plug seat is clean and free from cutting oils, chips, etc

INSTALL PROCEDURE

- The work area must be clean

- RS plug are ready to use as shipped, do not clean or oil the plug or stem

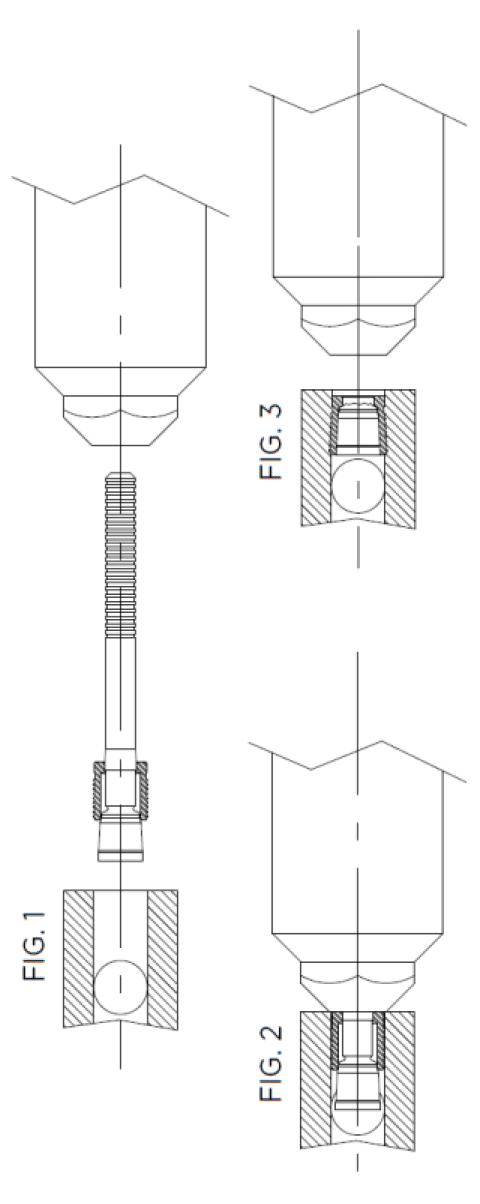

- Insert the shank into the tool, make sure the plug is against the nose of the tool (FIG.1)

- Insert the plug in the hole, make sure that the nose of the tool is pressed against the part and perpendicular (FIG.2)

- Activate the tool to expand the cork, the stem will break when reaching the expansion of the cork (FIG.3)

- Be sure to purchase the correct tool for each size of cap to be installed

REMOVAL PROCEDURE

- Using a punch, push the piece of stem out of the plug

- Remove the plug with a point and remove the piece of stem from the hole

- Make sure that you have removed chips, pieces of oil plug and any foreign bodies from the hole

- Install a new RS plug